Product Information

Efficient, Shock-Free Compression

- Helical screw rotors generate a balanced compression cycle

- Smooth and steady discharge eliminates the sudden release of trapped pockets of air into the line

- Contoured inlet and discharge ports minimize turbulence

Dependable Quality

- Superior and consistent quality is found in every CycloBlower as a result of:

- Continual investment in the training of world-class manufacturing personnel

- Quality inspections throughout the entire manufacturing process

- Compact design utilizing optimum performance materials

- Reduced vibrations result in longer service of critical blower components

High Capacity

- Industry unique rotor profile and accurately maintained tolerances allow the CycloBlower to operate at high speeds for increased capacity

Clean Air/Gas Delivery

- Contact-less rotors eliminates the need for lubrication within the compression chamber

- Outboard position of rotor bearings allows atmospheric venting between the compression chamber and the bearings and gears

- Prevents gear and bearing lubricants from contaminating the compression chamber for clean air/gas delivery

Installation Flexibility

- Units can be powered by various types of drives including electric motors, constant or variable, gasoline and diesel engines, or steam turbines

- May be connected through a variable frequency

- drive (VFD), V-belt, or direct drive to further improve efficiency

Low Installation Cost

- A special foundation is not required

- CycloBlower requires minimal floor space

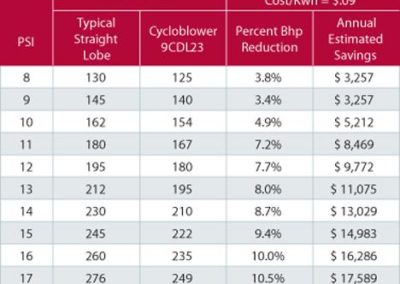

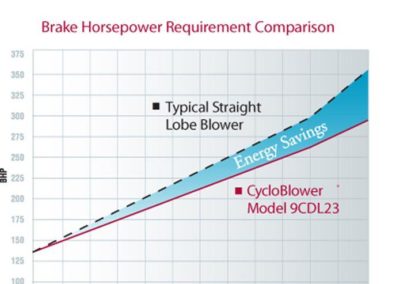

In many comparable applications, the CycloBlower operates more efficiently than other straight-lobe blowers. By requiring less brake horsepower, BHP, energy operating costs can be realized and reduced.

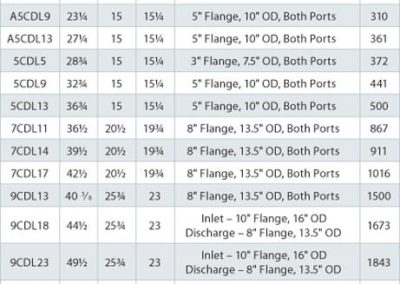

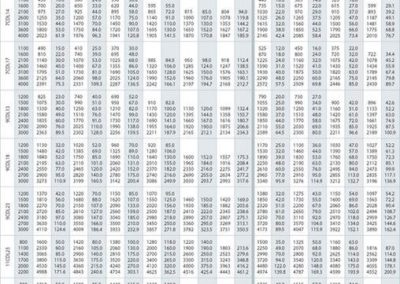

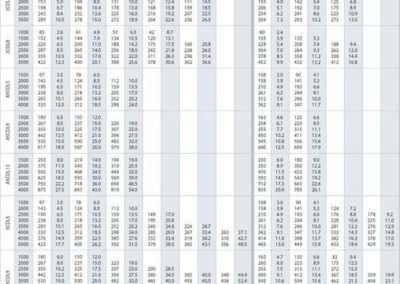

Product Specifications

-

Airflow Range:

6700 cfm -

Pressure:

20 psig -

Dry Vacuum:

17″ Hg -

Wet Vacuum:

24″ Hg

Product Features

- The CycloBlower stands out as the premium PD blower/vacuum pump in the market. The meshing of two helical lobe rotors synchronized by timing gears provides controlled compression of air for unmatched efficiency and shock-free discharge. State-of-the-art manufacturing techniques, improved assembly methods, and enhanced internal clearances allow the CycloBlower to operate at higher operating speeds for increased flow capacities. For optimal performance, we recommend AEONR PD and AEONR PD-XD (Extreme Duty for high ambient and/or high discharge temperatures) lubricants.

- Helical four-flute gate rotor and two-lobe main rotor are milled from high tensile strength ductile iron, stress relieved and dynamically balanced.

- One piece, high strength housing resists deflection to retain accurate running tolerances between rotors. Contoured porting provides smooth air flow.

- Anti-friction bearings carry the shaft loads in all models. CycloBlowers use pairs of angular contact ball bearings on the discharge end and cylindrical roller bearings or single-row ball bearings on the gear end. (Not standard on 3CDL models.)

- Synchronization of rotors is through a pair of helical timing gears. Precision alloy steel gears provide quiet, accurate operation.

- Hydrodynamic oil seals automatically push lubricant back towards reservoir for superior sealing

- Labyrinth-type shaft seals provide a minimum of controlled leakage of air or gas. Purged labyrinth seals or mechanical seals are available with units handling gas, where leakage cannot be tolerated. (Mechanical seals not available on 3CDL and A5CDL models.)

- Gears and bearings are lubricated by a splash oil system. (Not standard on A5CDL models.)

- CycloBlowers deliver clean, oil-free air to a wide range of global applications.

Industries & Applications

Industrial Processing:

- Recovery Air of Gas

- Combustion Air

- Air Drying

- Air Flotation and Sliding

- Blow-off Systems/Drying/Can Drying

- Carbon Black Coal Gasification

- Coke Oven Gas

- Gas Boosting

- Vacuum Systems

- Air Knife Stripping

Water Treatment:

- Pond Aeration

- Municipal or Industrial

- Wastewater Treatment

- Aeration

- Air Scouring

- Digester Gas Boosters

- Filter Backwashing

Particulate Handling:

- Clean Rooms

- Clean-Up

- Pneumatic Conveying

- Dry Bulk

- Fly Ash

- Source Capture

AutoVac will help determine which blower best fits your needs based on your application.